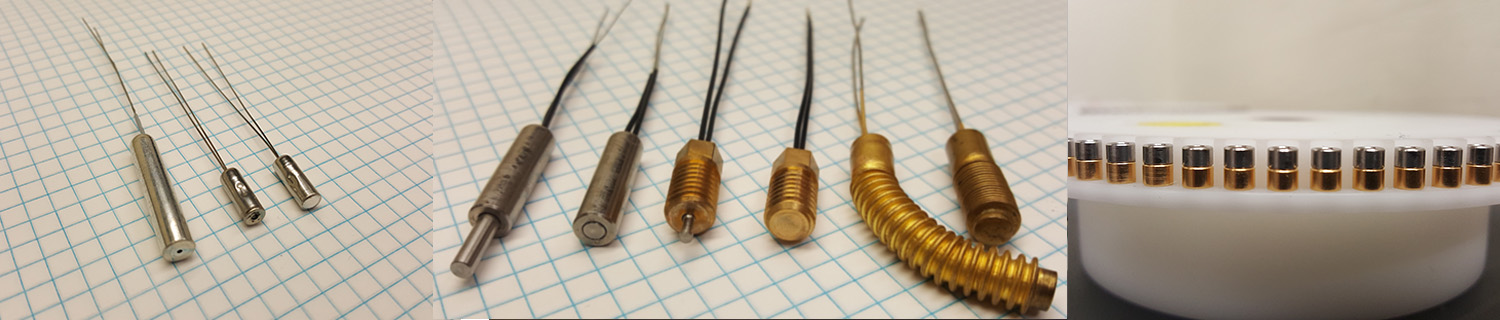

Bridgewire Welding

Bridgewire welding is comprised of microscopically spot welding or bonding or even soldering various alloys of resistance wire to two or more contacts to create an electric circuit. This hot-wire circuit can be created across an insulative glass, ceramic, or plastic gap.

The resistance wires typically range in size from .00013” to .0025” diameter and material selections involve nichrome, tungsten, stainless steel and platinum alloys just to name a few. Usually the customer supplies a part such as a glass to metal seal plug and specifies the wire size and material but Stored Energy Concepts, Inc. can be contracted to design the bridge system from specifications defining the number and type of contacts, size, material to ignite desired resistance range in ohms and available electrical energy for firing.